Introduction of Tyre

First Eng. Product made of polymers Only contact between vehicle & load

- Wheel invented 5000 years back

- 1845 :Air tube devise by Robert Will

- 1888 :First pneumatic tyre by J.B Dunlop

- 1948 : Radial tyres by Michelin

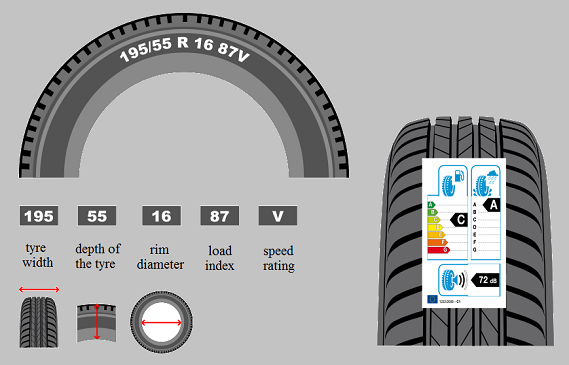

Tyre Size Explained

Width (A) – The tyres width measured in millimeters. In this example, tyre width is 195.

Profile / Aspect Ratio (B) – The profile is the depth of the tyre sidewall. This measurement is taken from the wheel to the outer circumference of the tyre and is a percentage of your tyre’s width. In the example above, depth of the tyre is 55.

Rim Diameter (C) – The diameter of the wheel rim measured in inches. In this example, the rim diameter is 16.

Load index – The load index on a tyre lets us know what the maximum load-carrying capacity of that tyre is. You are able to order a load index that is the same or above your vehicle’s standard requirement is.

Speed rating – The speed rating of a tyre lets us know the maximum speed in which the tyre has been tested corresponding to the tyres load index.

What is a tyre?

A tyre is a composite structure, i.e an assembly of interdependent materials with very diverse properties whose construction requires a high degree of accuracy.

It is composed of the following materials:

- An airtight, synthetic rubber liner

- The carcass ply

- The filler

- Beads

- Crown plies

- The tread

These elements are combined through vulcanization into single unit, using a mold that also forms the tyre’s final appearance (tread pattern and markings).

Basic requirement of tyre

- Tyre have four main functions.

- Support the weight of the vehicle.

- Transmit drive and braking power to the road

- Reduce the shocks transmitted from the road to the vehicle.

- Change and maintain the vehicle’s direction.

Type of tyres

A tyre is a composite structure, i.e an assembly of interdependent materials with very diverse properties whose construction requires a high degree of accuracy.

| Construction | Pattern | Designation | Application | |

|---|---|---|---|---|

| Bias | Rib | Numeric | Highway | Recreation |

| Bias Belted | Lug | Alpha Numeric | OTR | Garden |

| Radial | Semi-lug | Millimetric | Farm | ATV |

| Tubless | Block | Aircraft | Winter | |

| Smooth thread | Racing | Forestry | ||

Carcass

The backbone of a tyre is called the carcass. This interior layer consists of overlapping synthetic cords called Piles. The angle of these plies will largely determine a tyre’s strength and flexibility in action, while the entire carcass construction will affect a tyre’s performance and wear. Bias-ply tyres have piles running diagonally from one bead to the other, with alternating plies angled in opposite directions. The cords form an X.

- Contact patch

- When a tyre rolls, the part that hits the road flattens out, becoming the contact patch. As forward motion continues, the contact patch travels away from the road and returns to its rounded shape. This constant flexing from round to flat causes plies to rub against each other, generating heat

- Bead

- The bead is the inner diameter edge of the tyre, comprised of high tensile steel wires. It’s the edge of the sidewall where the tyre seats against the rim, providing an airtight fit, and it acts as an anchor to the plies

- Tread

- It is the outermost region of the tyre pressing against the road. Molded from tough rubber, the surface of the tread is crisscrossed with grooves called sipes, whichchannel water away from the contact patch to prevent hydroplaning. The entire tread affects cooling, wear and stability, and traction

- Sidewall

- The tyre’s sidewall is the portion of the tyre between the bead and the tread. It’s flexible enough to cushion bumps, yet stiff enough to limit rollover and protect theside of the tyre from road damage.